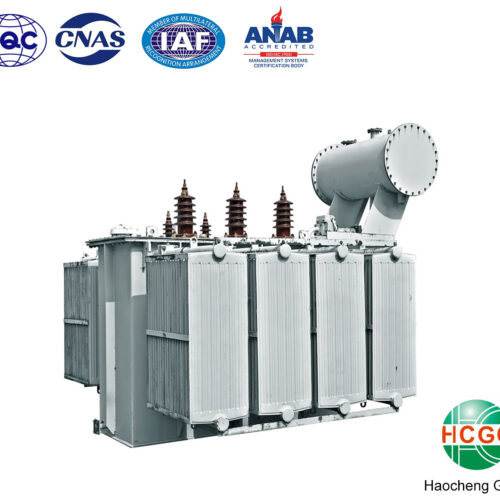

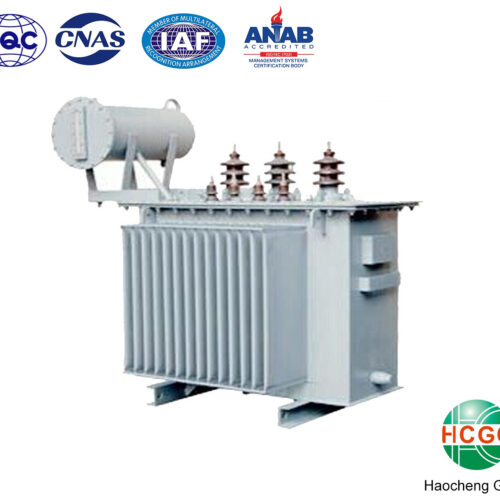

The triangular three-dimensional wound core’s flux uniformity (increased by 40%) and low loss characteristics make it a leader in energy efficiency, quietness and reliability.

The triangular three-dimensional wound core significantly reduces magnetic resistance and magnetic leakage by eliminating the air gap in the joints and optimizing the magnetic circuit. The traditional laminated core has uneven magnetic flux distribution due to the gap between the laminated cores.

The 3D Wound Core Distribution Transformer represents the direction of high efficiency and environmental protection in transformer technology, and is particularly suitable for scenarios with high requirements for energy efficiency and reliability.